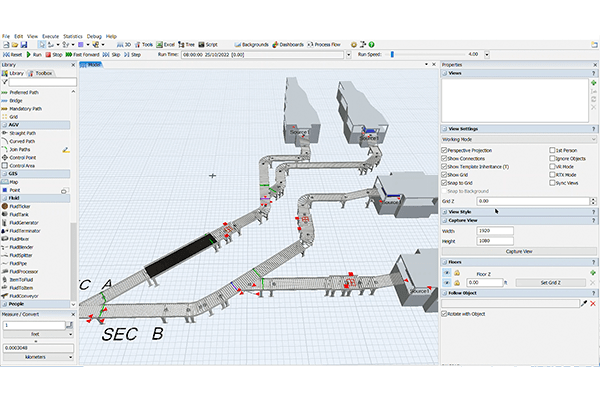

Software simulation advantages (Flex Sim)

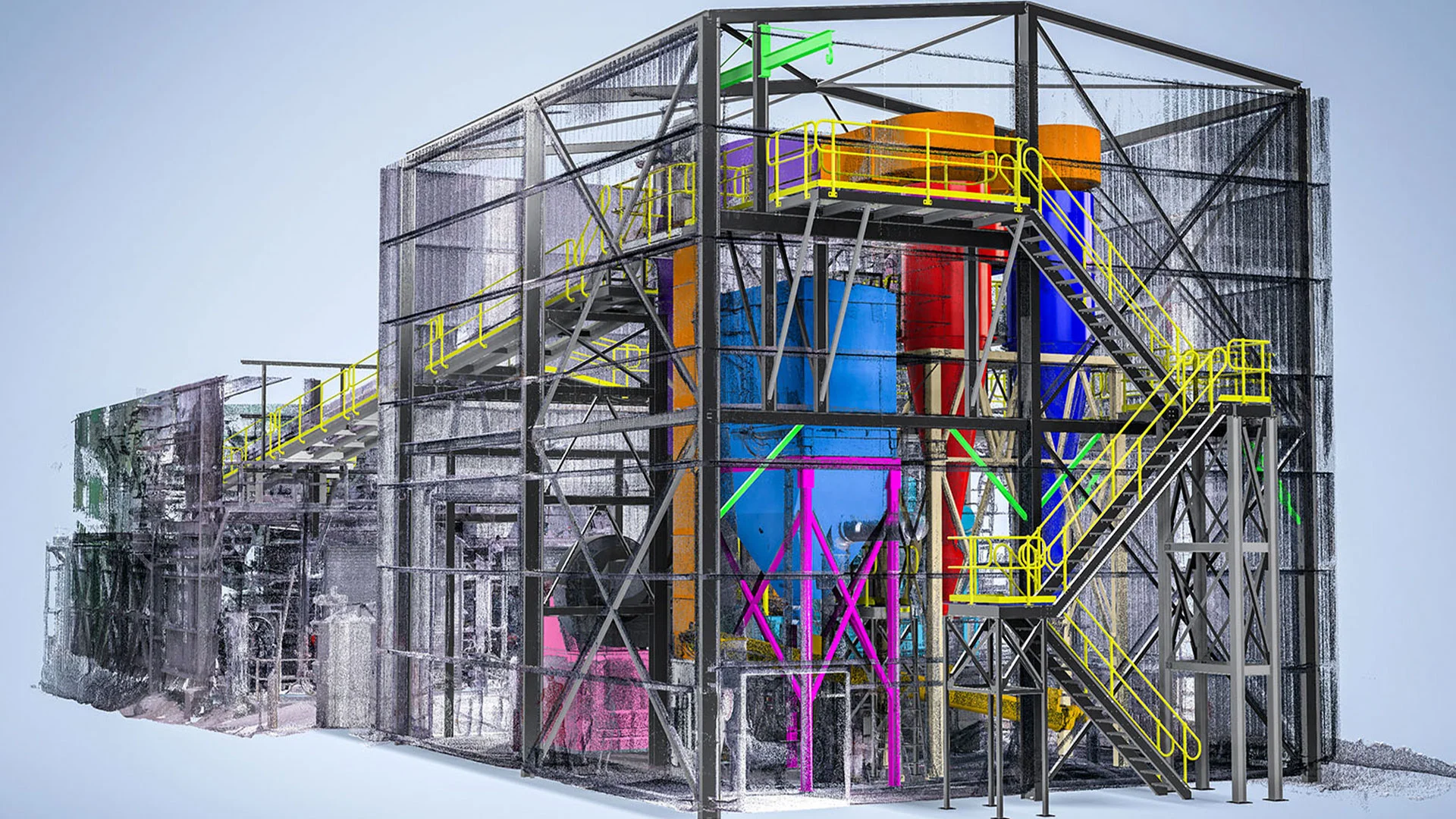

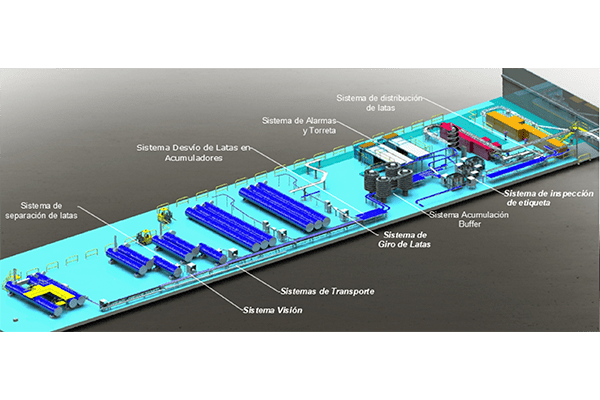

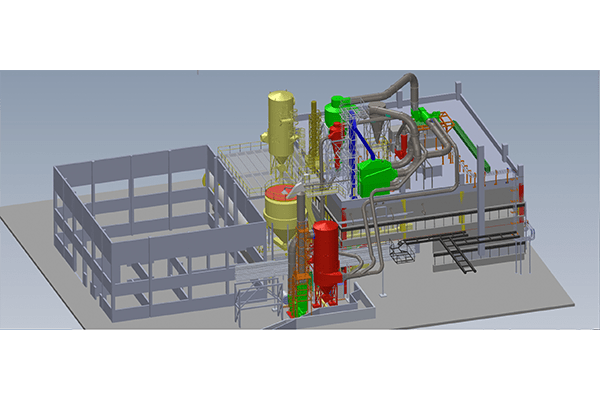

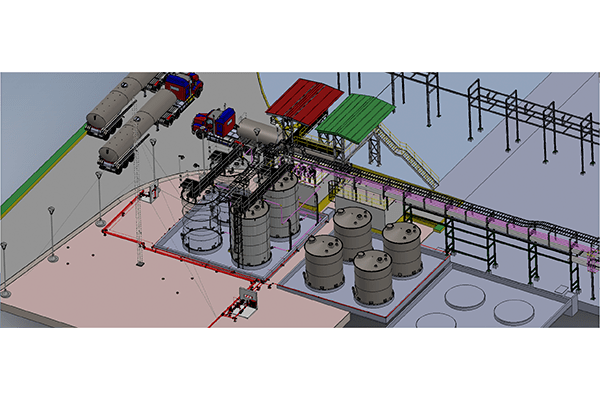

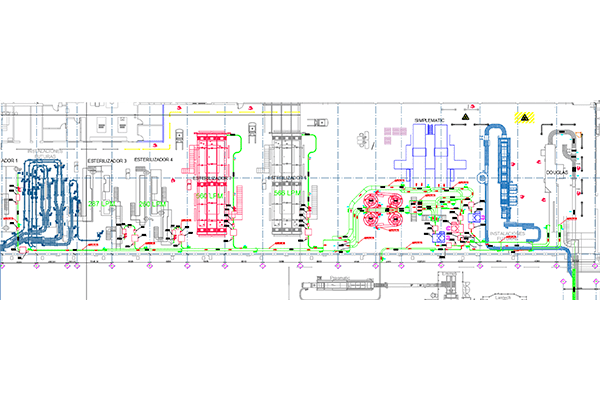

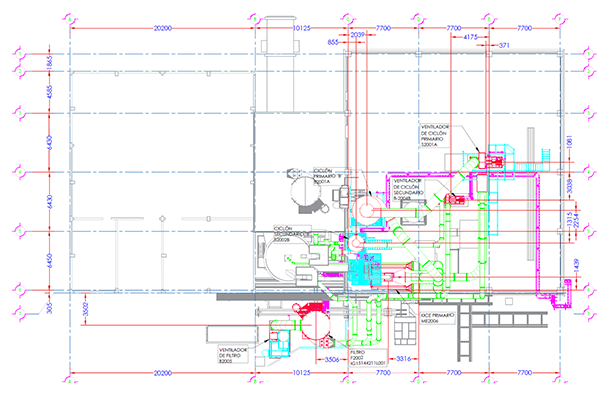

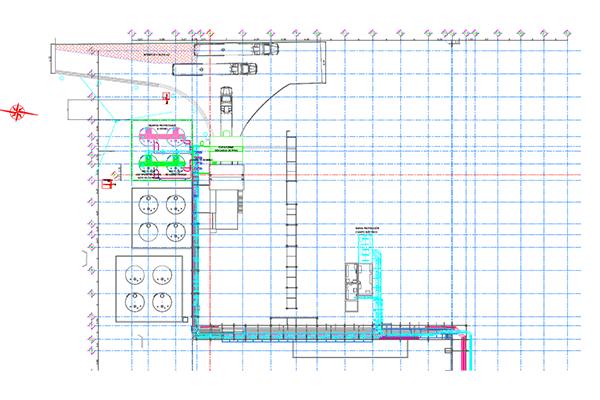

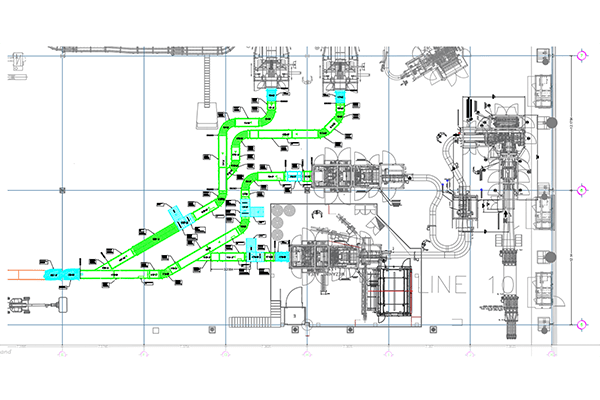

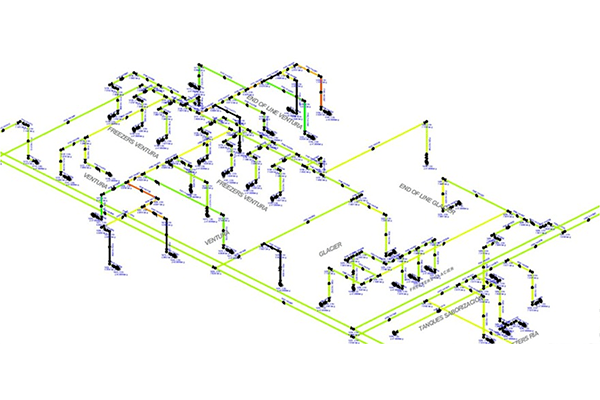

With FlexSim Software Simulation, complex industrial processes can be analyzed and optimized through detailed 3D modeling. This technology allows teams to evaluate every operational aspect and make informed decisions by visualizing the potential impact of changes or system additions before implementation.

Through simulation, process constraints can be easily identified, and in the event of a sudden stoppage, it becomes possible to determine the available recovery time before a full line shutdown occurs. The tool also enables users to visualize and analyze accumulation and buffer systems, obtain precise information on operating times, and test multiple scenarios prior to installing or purchasing equipment.

By incorporating FlexSim during the engineering stage, decision-making becomes more accurate, efficient, and cost-effective — ensuring that each project is designed with full awareness of its operational performance.